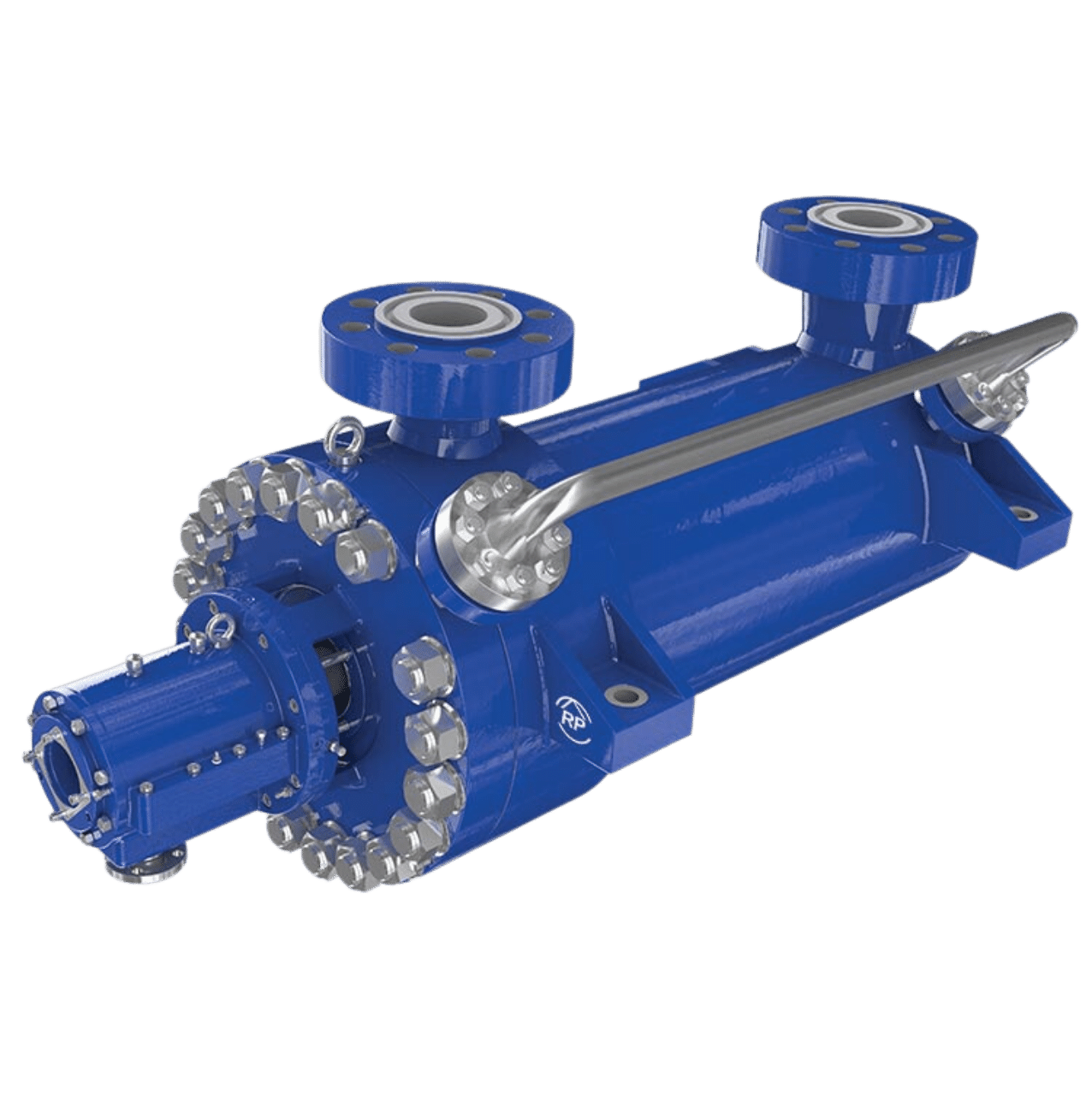

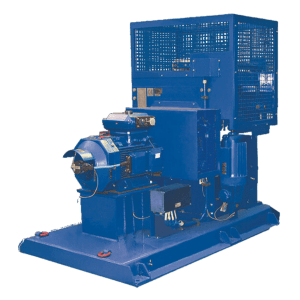

ADC Jet Water Pump

Decoking Jet Water Pump

Designed to handle the extreme conditions of Hydraulic Decoking Systems, the ADC model is part of the A-Line range of heavy-duty barrel pumps. It has been engineered to cut the solid coke out of the drum by water jet.

OPERATION LIMITS:

Capacity: up to 400 m³/h (1,761 gpm).

Head: max. 3,600 m (11,811 ft) for flange class 2500.

Maximum Pressure: up to 350 bar (5,076 psi).

Temperature: standard up to 65 °C (149 °F).

OVERVIEW

See the A-Line pump range for more information on Ruhrpumpen’s heavy-duty barrel pumps.

CHARACTERISTICS AND DESIGN FEATURES

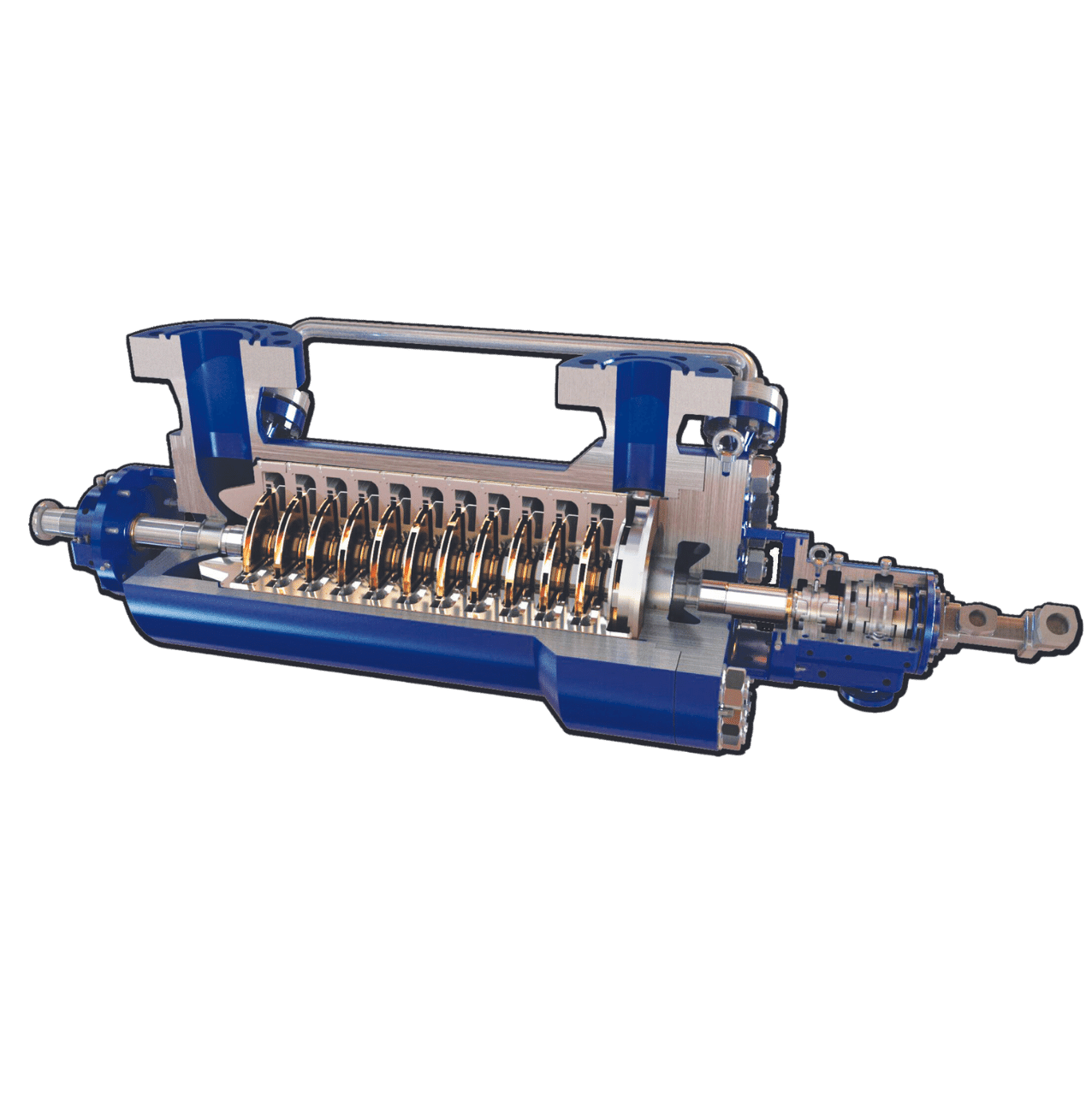

Heavy-duty barrel pump design according to API 610 latest edition (BB5 type).

- Horizontal multi-stage pump with in-line impeller arrangement

- Single suction impellers

- Double casing

- Radially split

- Centerline mounted centrifugal pump with axial thrust compensation by balancing drum

- Top-top suction and discharge nozzles

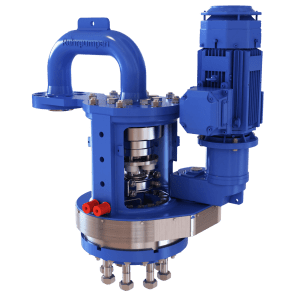

CONSTRUCTION MATERIALS

- Material combinations per API 610 standard (C6 modified for decoking)

- NACE version is available.

BENEFITS

- Available in two casing versions: forged and cast

- Two inner element versions: standard with rigid casing and full pull-out

- Full closed stator vanes integrated into the stage casing

- Shaft sleeves integrated into the large impeller hub

- rigid rotor design or large shaft wet running class

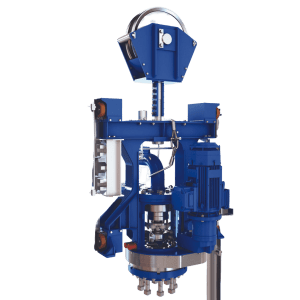

OTHER DECOKING COMPONENTS AND SERVICES

We supply engineering services and heavy-duty components for Hydraulic Decoking Systems, including:

- Coke Cutting Tool

- Crosshead with Free Fall Arrestor

- Drill Stem Drives (Rotary Joints)

- Hoists: Electric / Hydraulic / Pneumatic

- Decoking and Isolation Valves

- Water Jet Pumps

Moreover, our Global Service Network is fully equipped to offer spare parts and repair services for decoking equipment and systems. Our experience includes Freefall Arrestor revamps and retrofits without interruption to existing operations.

DOWNLOADS