Reverse Engineering

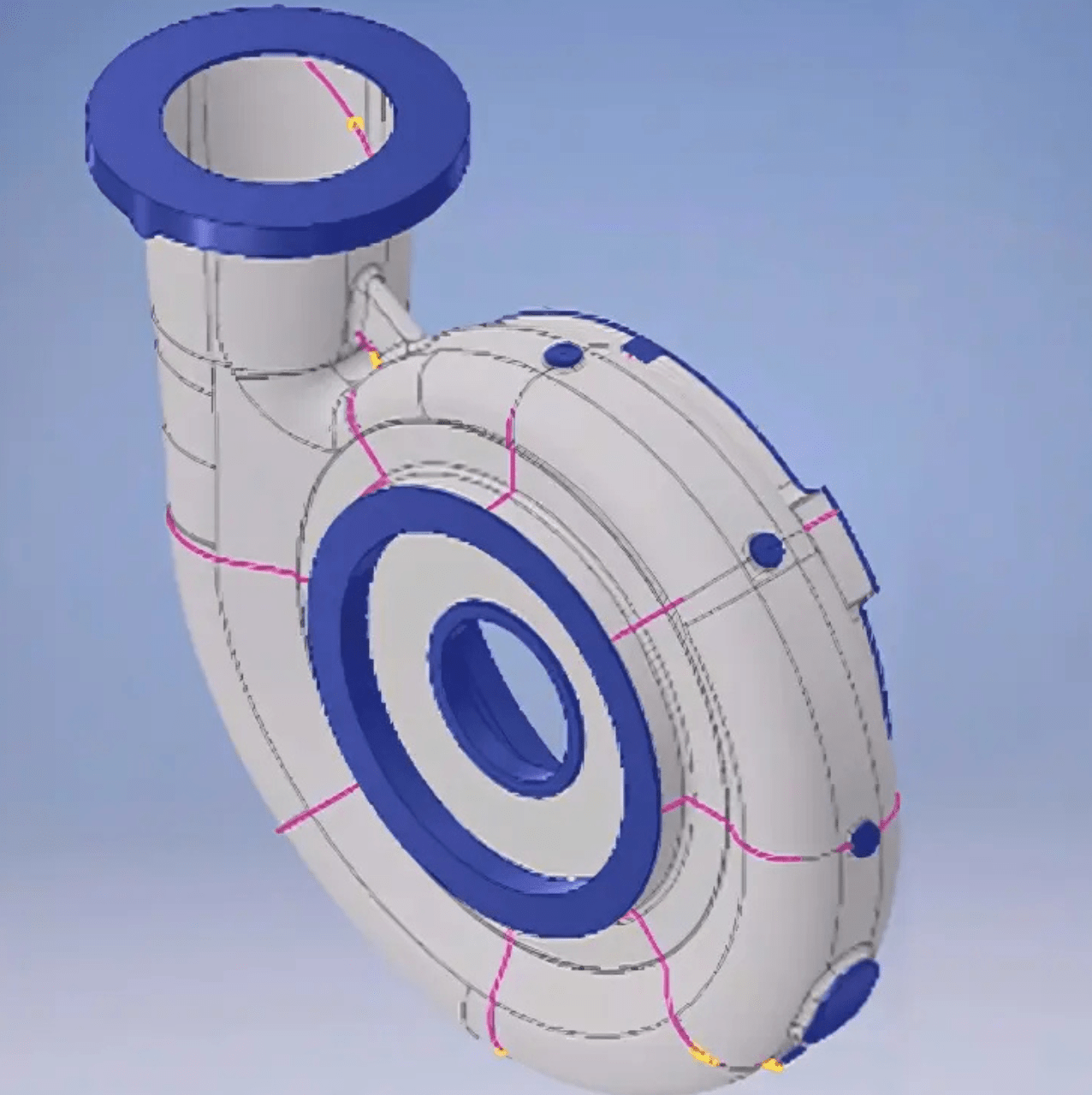

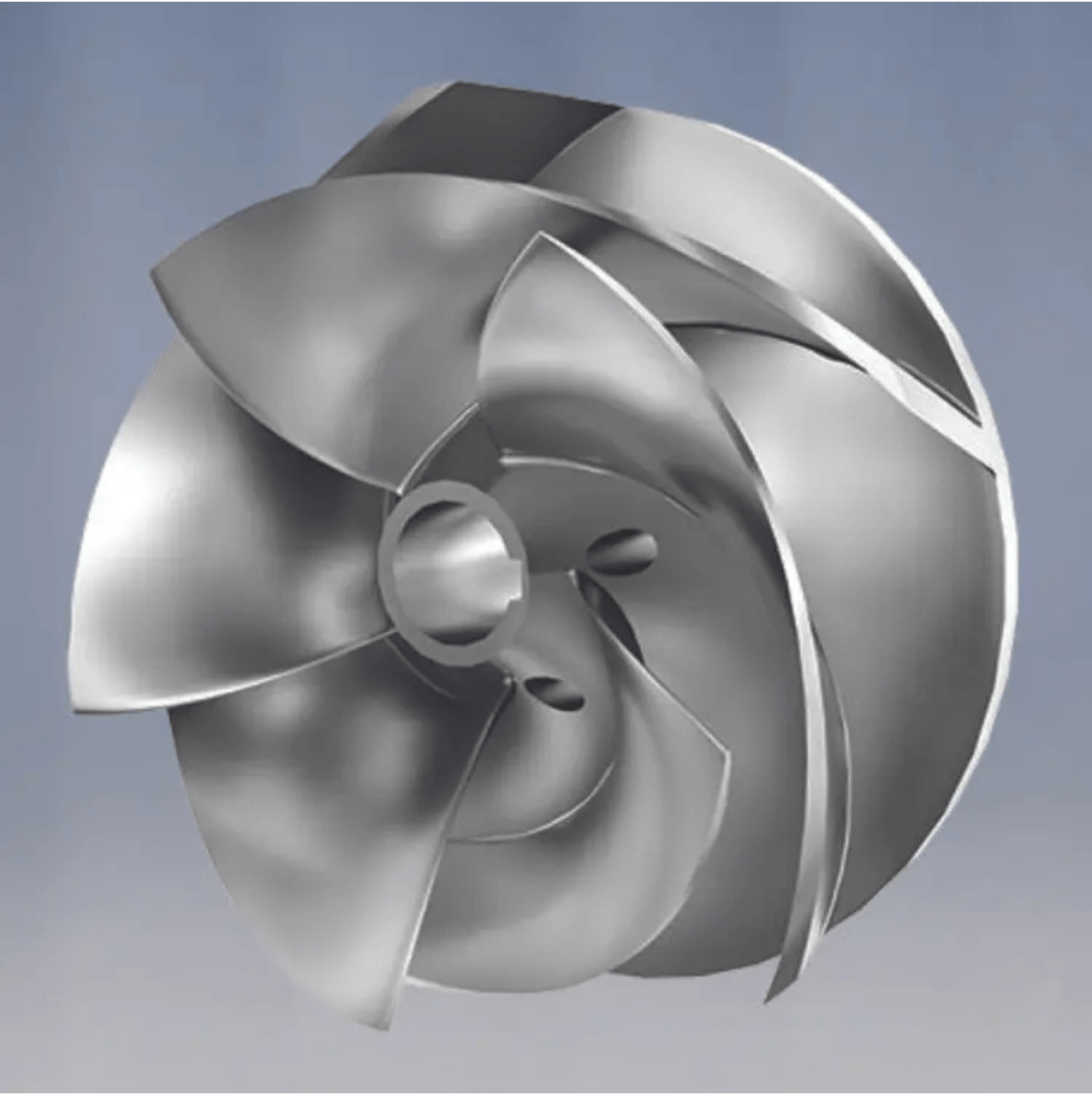

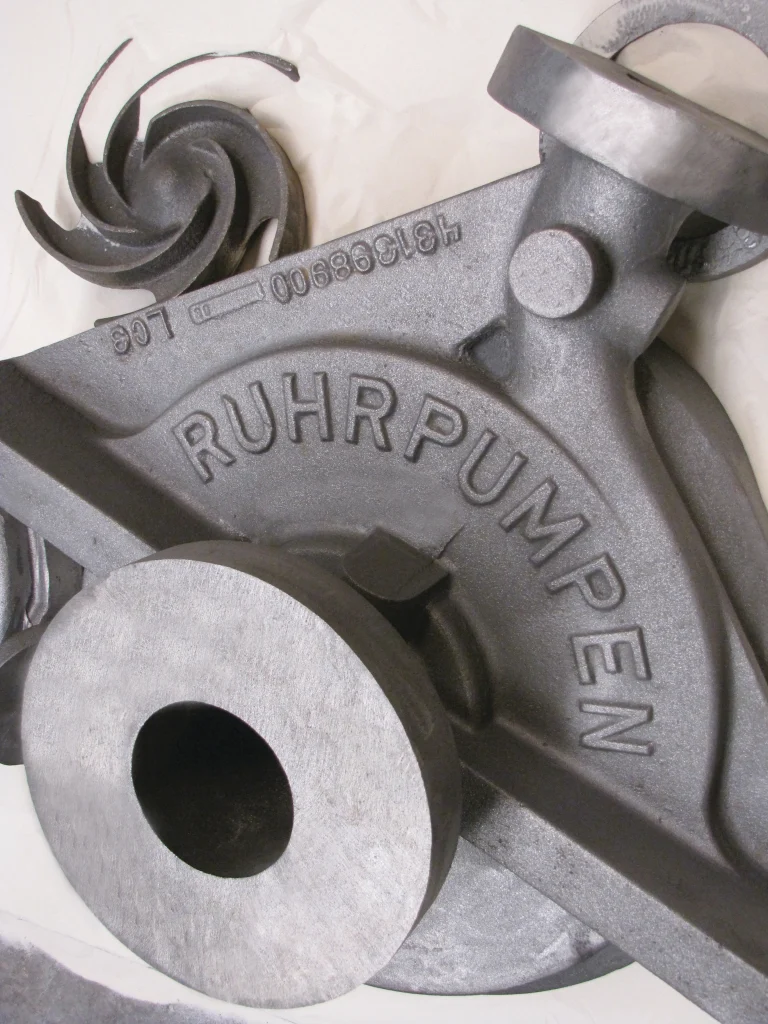

Our solution to provide customers access to worn or obsolete pump parts, material upgrades and design improvements for any pump. Re-Engineering is not replicating, it’s improving the current design, extending the parts life cycle and reducing operating down times. When possible, we can improve hydraulic efficiency, ultimately reducing energy and operating costs for you.

Along with our Re-engineering service and our Additive Manufacturing technology paired with our Global Parts Manufacturing Center, we can achieve quick turnaround for finished machined parts.

Re-Engineering as a Service

We can re-engineer your non-Ruhrpumpen pump parts, delivering new, ready to use machined parts while improving them in the process.

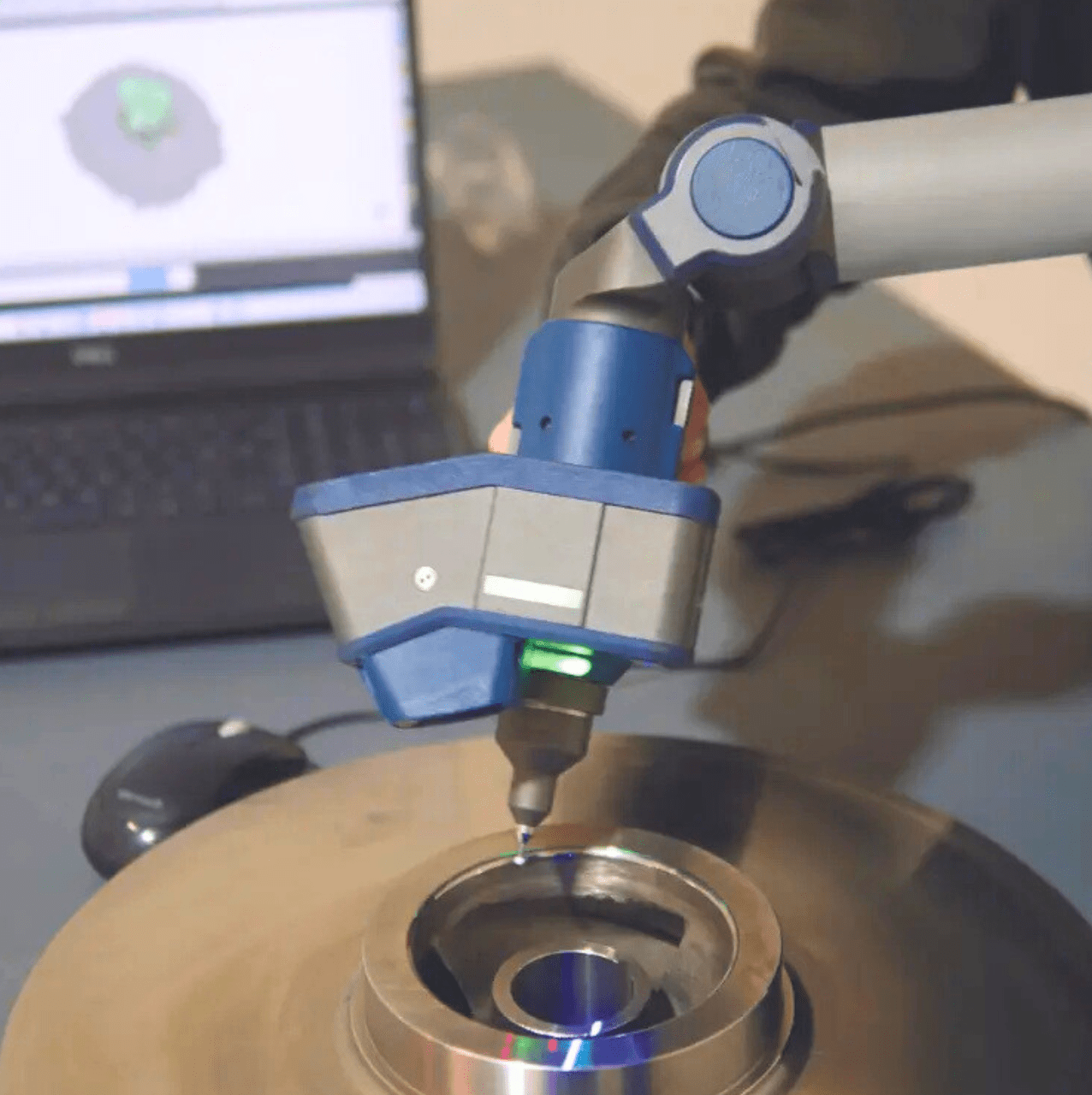

There are many customers in need for non-Ruhrpumpen spare parts that are either no longer available or have great lead times from their existing OEM. Our team scans your parts using the latest all in one PCMM and dedicated reverse engineering software’s to then digitize into detailed 3D Models.

Ruhrpumpen’s Hydraulic Engineering Department provides support by validating our hydraulic designs, making sure we exceed the originally designed part.

REAP paired with our additive manufacturing services provides spare parts in a matter of weeks. Our AM service allows us to decrease casting lead times and achieve dimensions closer to the original CAD Design.

Re-Engineering Process

Scan and Measure.

PCMM/Laser Hand measurements Pictures

Recreate 3D Model

Review captured information

Improve and Validate Design

Materials Design improvements

Release for Manufacturing

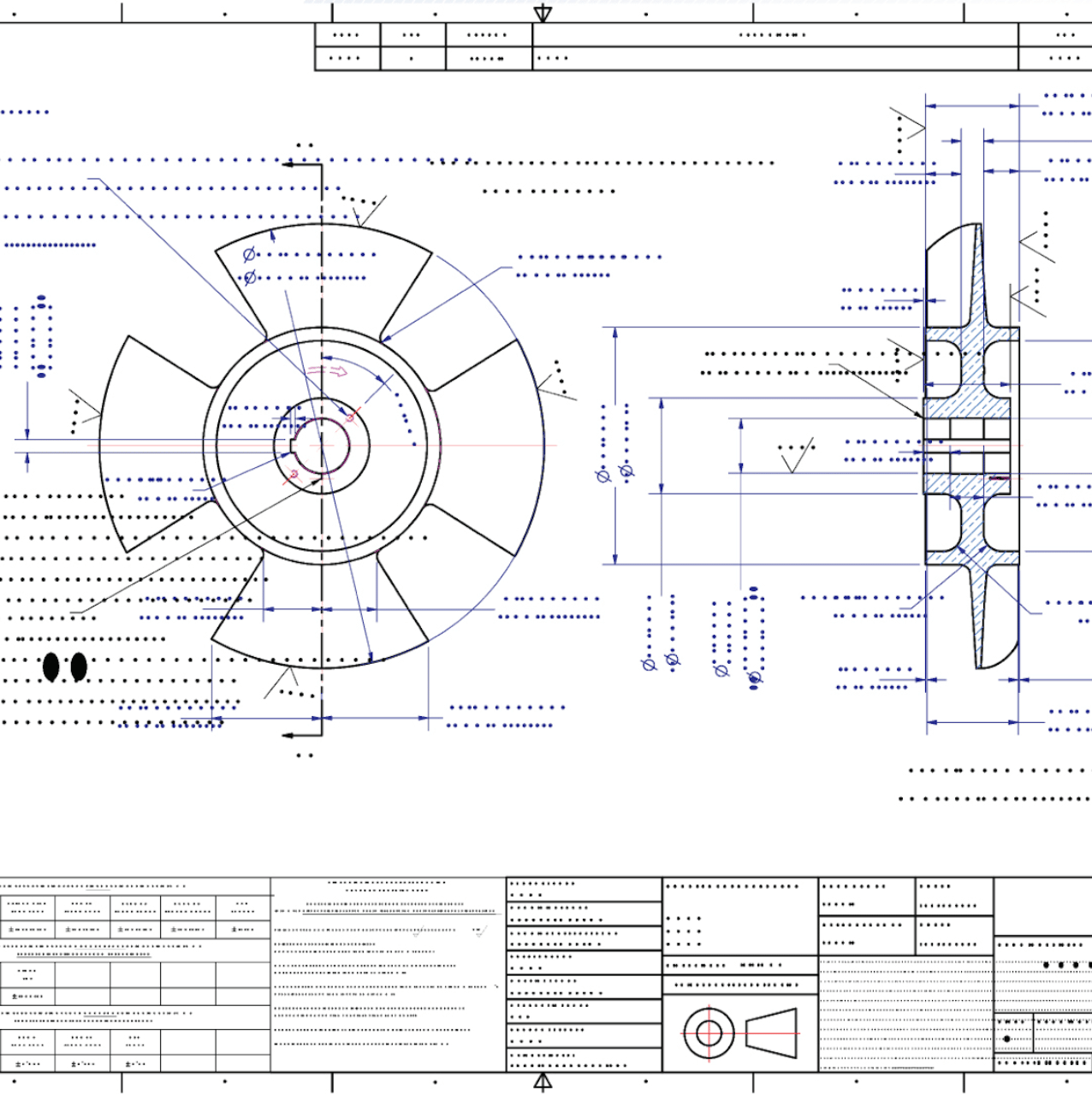

Machining drawings, casting drawings

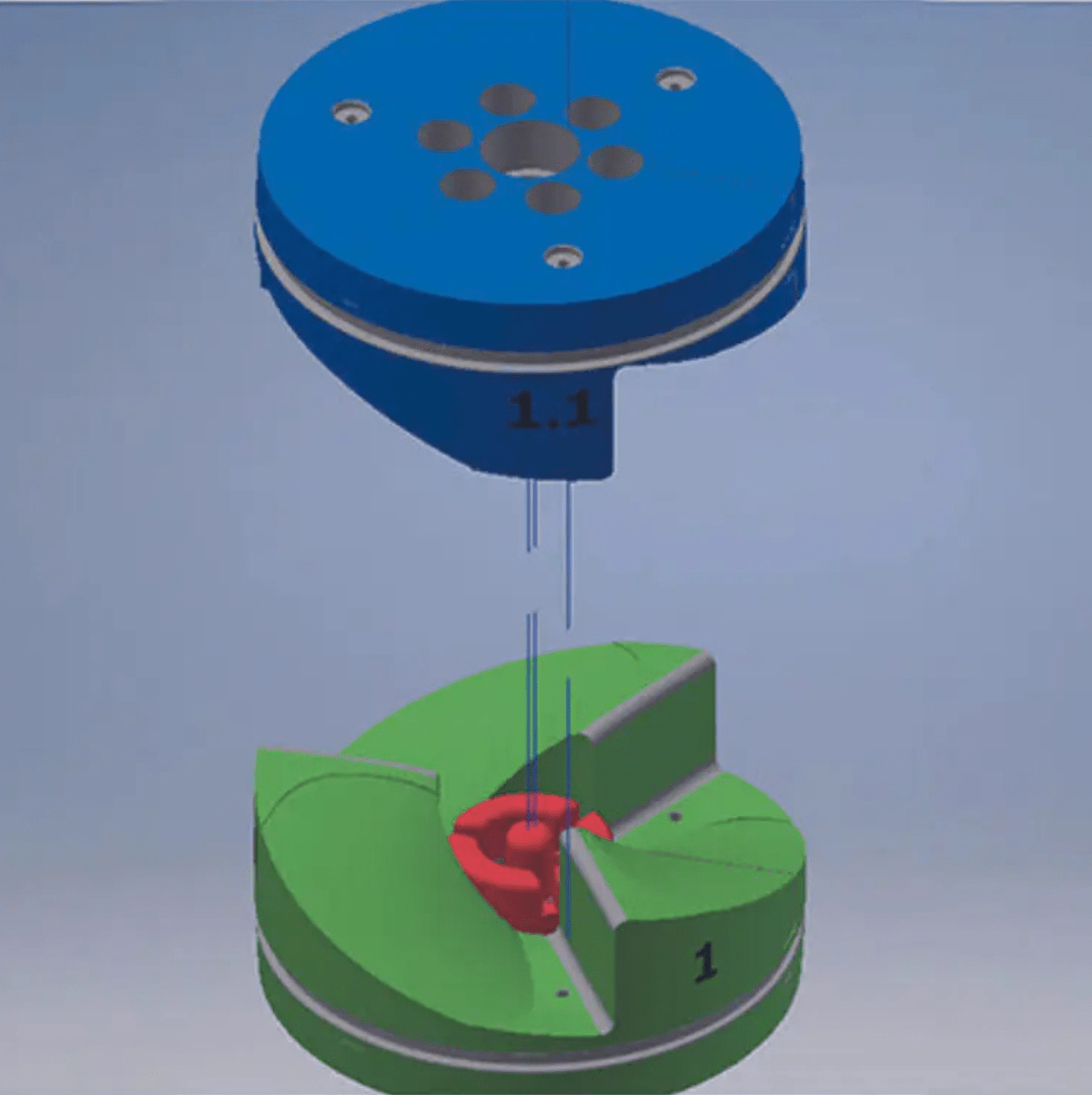

Additive Manufacturing Design

Design feeding and gating Casting simulations Design core and mold

Print and clean printed parts Ship

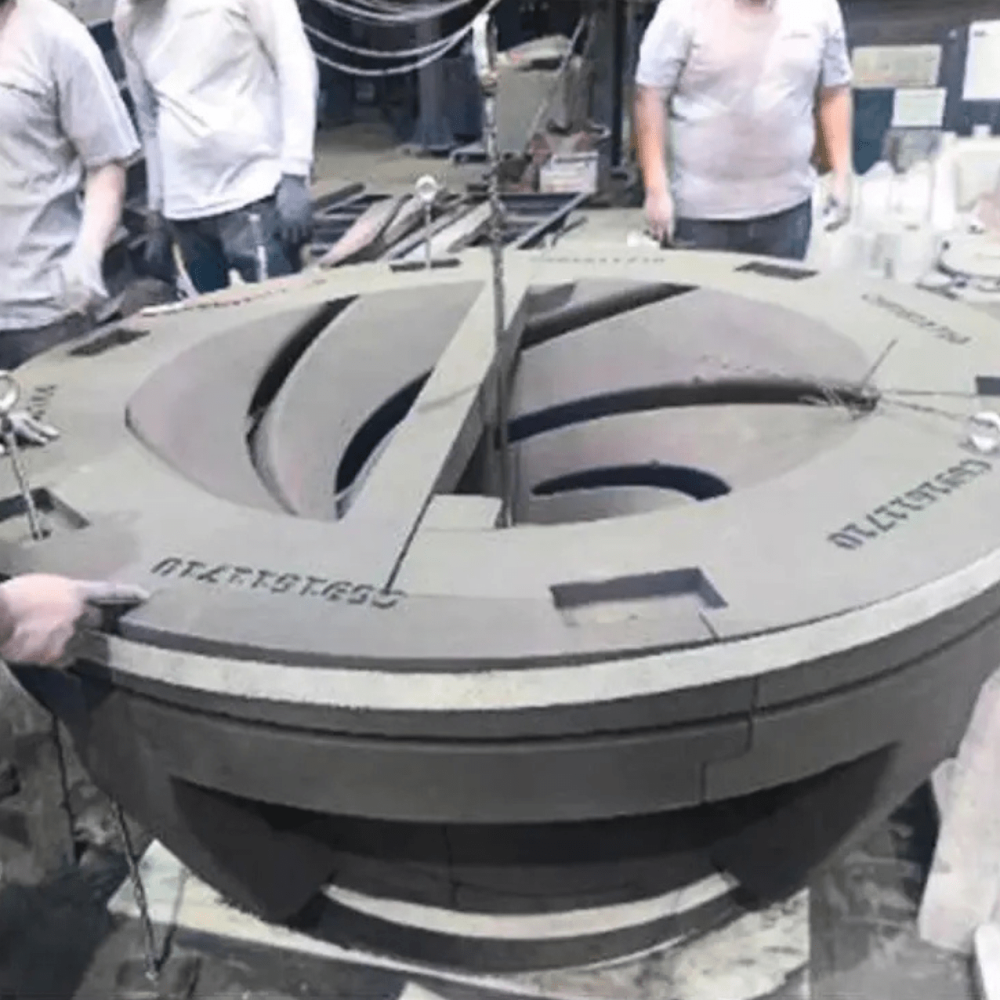

Casting

Cores and molds get assembled Poured and cleaned

Customer Benefits

- Supply of obsolete components

- Improved efficiency

- Improved mechanical and hydraulic performance

- Reduced operating and maintenance costs

- Our parts can be applied to pumps manufactured by other companies